Moore’s Law is the observation that the number of transistors in an integrated circuit doubles every two years. Named after Gordon Moore, the co-founder of Fairchild Semiconductor and former CEO of Intel, Moore’s thoughts in 1965 were less of a measurement, and more of a challenge to the industry for the pace of future developments.

It was Caltech professor Carver Mead who popularized the term “Moore’s Law” in the late 70’s, when it became a shared competitive goal among players in the semiconductor manufacturing space. Since 1975, the goals pioneered by Moore’s thoughts have largely stood up. Those of us who are old enough remember the computers of the 80’s, the cell phones of the 90’s and the iPhone of 2007. Each was a breakthrough in its day, and each is woefully inadequate today. That is Moore’s Law at work.

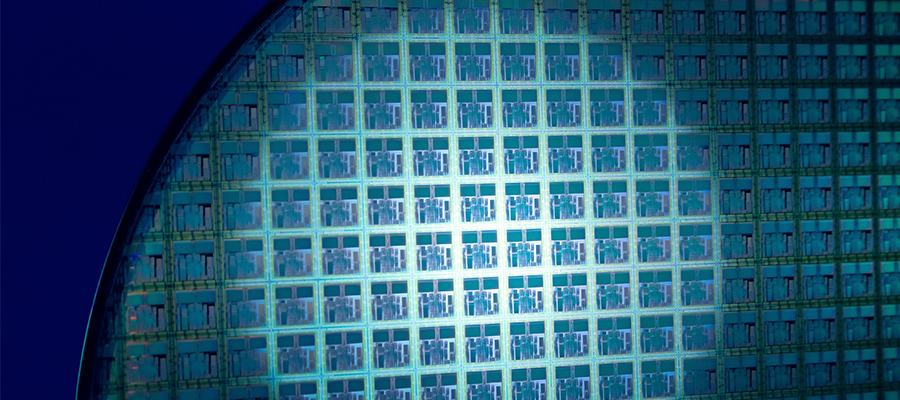

Another way to state Moore’s law is that every two years, the size of the transistors in integrated circuits is cut in half. Today’s transistors sizes are just a few nanometers (a nanometer is roughly 10 atoms across) and ten thousand transistors lined up side by side are less than the width of a human hair. With such small sizes, it is easy to imagine how any small imperfection could ruin an entire microchip.

For people in the semiconductor manufacturing business, MATHESON needs no introduction. MATHESON has been supporting the semiconductor fab business with our ultrapure products for decades. MATHESON has worked, and evolved, side-by-side with technology innovators in both academia and industry. As the transistor sizes have shrunk, we have produced gas products at higher purities with tighter specifications to enable higher fabrication precision, smaller scale, and fewer defects. These include pure and dopant mixtures, etchants, process gases, new materials, purification technology and gas handling equipment. A good example is MATHESON’s Etch 5 Grade SiCl4 which was developed to reduce “first wafer” scrap that customers experienced with standard SiCl4 due to variable etch rates. The Etch 5 Grade SiCl4 dramatically reduced or eliminated first wafer scrap by providing a much more stable etch rate.

MATHESON has also developed new analytical methods to allow for the detection of the most miniscule impurities to allow for the extremely clean and pure gases that the ever shrinking transistors require.

The R&D team in MATHESON’s Advanced Technology Center in Longmont, Colorado has achieved a milestone in purifier capability to remove Total Organic Contamination (TOC) in inert gas. The R&D team has developed a NANOCHEM® purifier, INX-Plus™, that removes hydrocarbons to less than 426 ppq (parts per quadrillion). A ppq is 1×10-15. The INX-Plus™ purifier was used in gas phase argon and demonstrated that Xylene could be removed down to 426 ppq when challenged with 100 ppb of the hydrocarbon. These levels are difficult to achieve due to the complex interactions that are necessary for the impurity to be removed at these levels as well as the sophisticated analytical techniques that had to be developed in order to measure such low levels.

At MATHESON we consider ourselves to be partners in the development of advanced integrated circuits, not simply suppliers. Let MATHESON help you achieve the future advances required to continue Moore’s Law.