Gas Purifiers and Filters for a variety of applications.

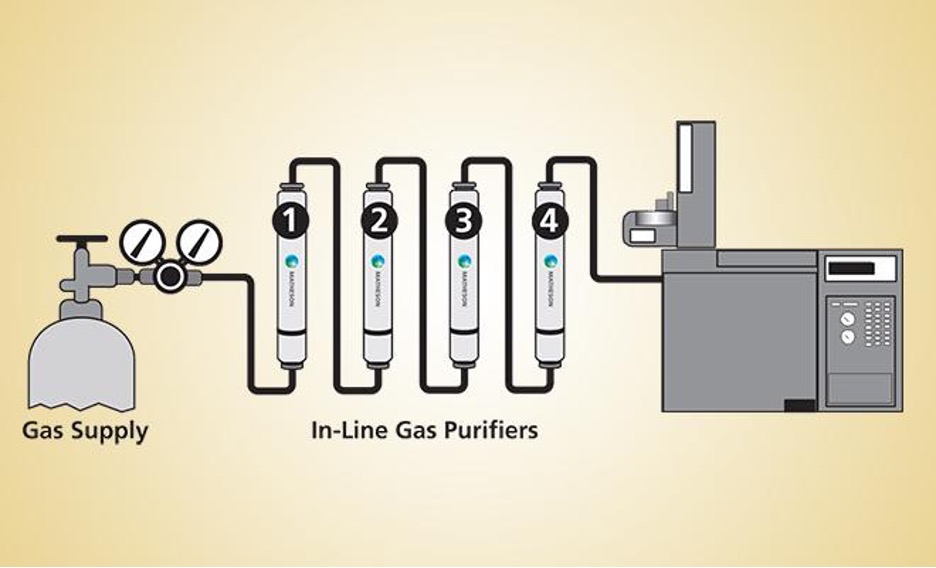

Gas Purifiers include in-line and cartridge types for removal of oxygen, hydrocarbons, and water.

Gas Filters include all-welded depth filters, high-pressure filters, and high purity membrane filters.

Visit our Online Store for selection, specifications, and ordering information for all of our gas purifiers and filters. The MATHESON Online Store does not require pre-registration, and accepts major credit cards. We also support tax exempt purchasing, if your organization is qualified.

Gas Purifiers

Purifiers remove specific chemical components from a gas stream. They function by either catalytic action or by adsorption.

When saturated, some purifiers must be replaced, while others can be regenerated.

It is important to realize that purifiers are not filters, which function differently.

About MATHESON Gas Purifiers

MATHESON offers a wide range of purifiers including oxygen removing, moisture removing, and oil (hydrocarbon) removing types.

To improve and support laboratory performance, MATHESON offers PUR-Gas, an innovative series of cartridge-type and in-line purifiers for point-of-use applications. These systems allow easy replacement of the exhausted cartridges within seconds without the use of any hand tools, thus minimizing operating downtime.

The PUR-Gas purifiers are available to remove moisture, oxygen, and hydrocarbons. In addition, a PUR-Gas System for nitrogen is also available to enhance LC/MS instrument operation.

Also see the MATHESON Nanochem® purifiers – suitable for UHP requirements in a variety of applications, including semiconductor manufacturing.

Gas Filters

Filters remove particulate matter from the gas stream. The ideal placement of filters is just before the point-of-use of the gas, in order to trap any particles generated in the delivery line or from the source.

About MATHESON Gas Filters

They utilize various types of filtration media for a specific application to limit travel of particulates by size through them. The size (diameter) of the smallest particles removed is expressed as the performance rating of the filter, generally expressed as microns.

MATHESON offers high purity depth filters that provide 100% filtration efficiency at a 0.2 micron level. Membrane and ceramic type filters have a 100% filtration efficiency rating at a .01 micron level.

The useful lifespan of filters varies by application. The primary factors that determine the useful life of the filter:

- Particulate size and density in the supply line

- Active usage time (duty cycle)

In general, filters should be replaced when the pressure drop across the filter (upstream to downstream) increases by approximately 50%.