MATHESON gas supply options address the full scope of possible requirements for gas delivery, storage and supply – from the construction of onsite plants to the delivery of the smallest lecture bottle.

Requirements for gas delivery and storage can vary based on rate of consumption, purity, application and suitability of the gas itself.

Onsite Production and Pipeline Delivery

Onsite Production

MATHESON gas supply options are scalable to customer requirements, and onsite supply is the option that puts the production plant directly at (or near) the customer’s site.

Even the highest rate of demand can be met with a MATHESON-designed and MATHESON-operated production facility constructed on the customer site.

Atmospheric gases in liquid phase (nitrogen, oxygen, argon) are produced by the process of cryogenic air separation. The liquids are stored in cryogenic vessels. Gas phase production of nitrogen and oxygen is possible by non-cryogenic air separation, usually using pressure swing adsorption (PSA).

Hydrogen and carbon monoxide are produced most typically by steam methane reforming (SMR) of natural gas. Other gas products, including compressed dry air and carbon dioxide are also possible.

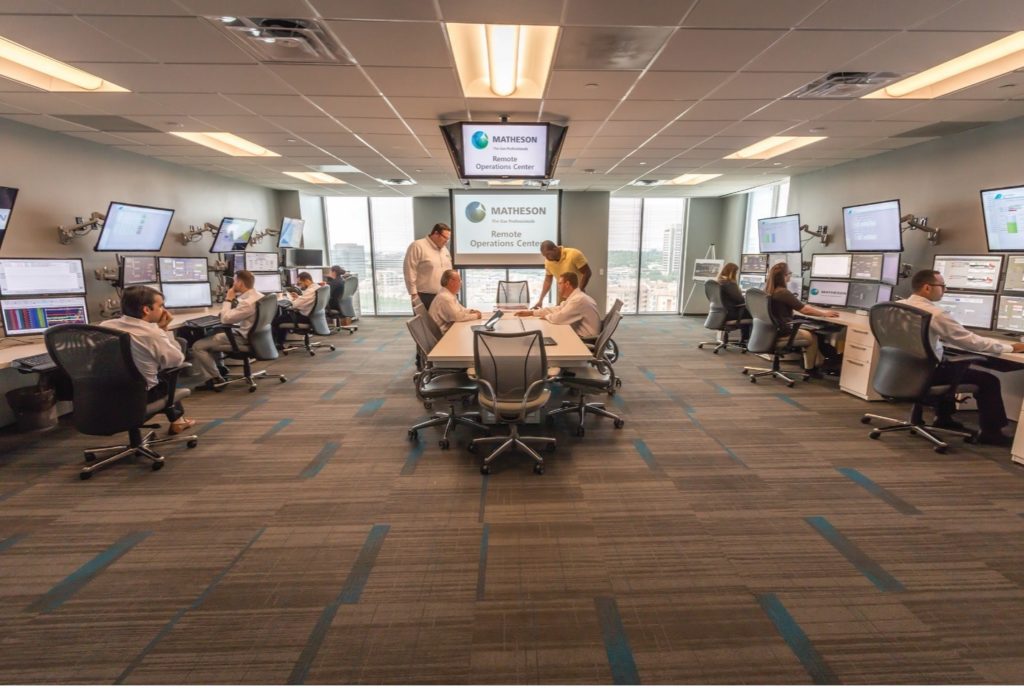

Onsite plants are typically owned and operated by MATHESON, with operations oversight supported 24-7-365 by our expert teams at our Remote Operations Centers.

Read more about Onsite Production in the Plants and Engineering section:

Pipeline Delivery

When onsite production of nitrogen or oxygen is not practical, but demand is still high, pipeline delivery of gas phase nitrogen or oxygen can be provided from a nearby air separation unit. Hydrogen may also be delivered by pipeline.

Pipeline delivery of gas is limited to the service area of a suitable production site.

See our Plants and Engineering section for more information on Pipeline Gas Delivery of oxygen and nitrogen.

Bulk Supply

Liquid Phase Bulk

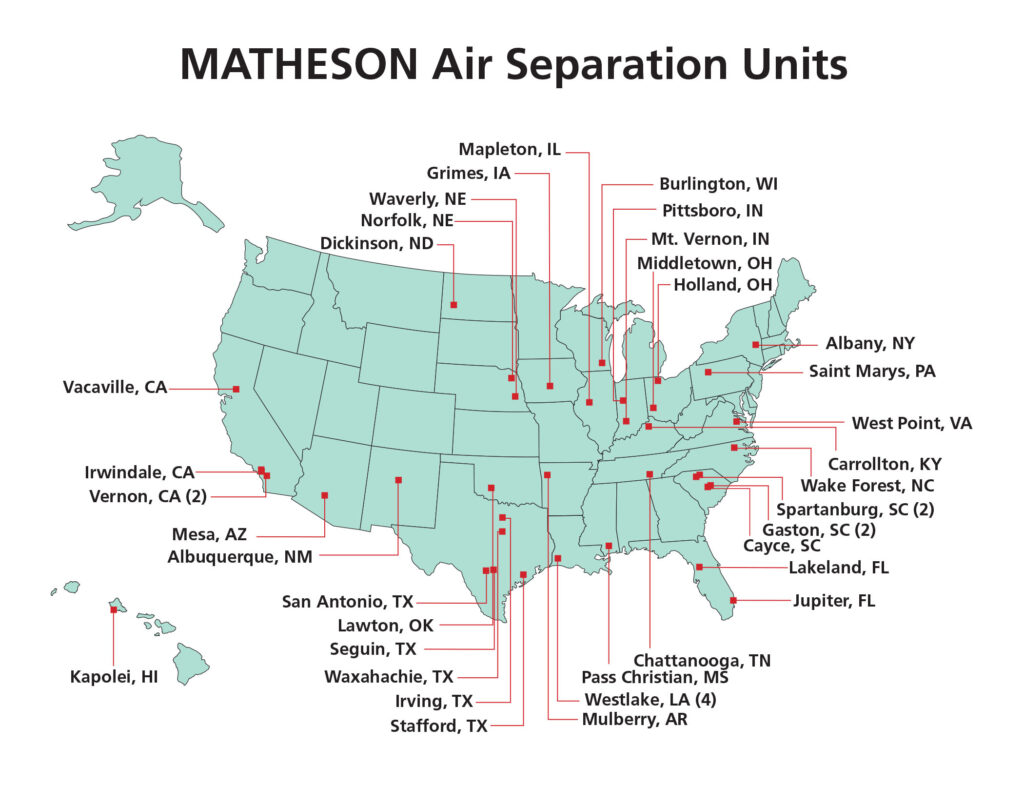

MATHESON cryogenic transport trailers with capacities of up to 7,000 gallons can deliver liquid oxygen, liquid nitrogen, and liquid argon (atmospheric gases) to MATHESON liquid storage vessels at customer sites. Our fleet of air separation units (ASUs) enables bulk delivery of atmospheric gases coast-to-coast, including an ASU in Hawaii.

MATHESON onsite customer storage vessels range from 300 gallon to 30,000+ gallon capacities. MATHESON professionals support construction of the pad on which the vessel is placed, perform installation of the cryogenic storage vessel(s), conduct routine inspections, and carry out maintenance and necessary repairs.

MATHESON bulk customers are supported by the centralized MATHESON Bulk Logistics team advanced telemetry, and a 24/7/365 response team to ensure safe and timely deliveries of cryogens, including access to emergency supply.

Liquid Phase MicroBulk

As the names imply, MicroBulk containers perform the same basic function as the larger cryogenic storage vessels, but on a smaller scale.

Conventional cryogenic storage vessels require installation on a pad and site preparation (typically requiring sanction and inspection by local regulatory authorities). MicroBulk is a gas supply option that typically requires less rigorous site preparation and is normally subject to fewer regulations.

Liquid Phase Bulk Tanks

Not all bulk liquids are delivered by tanker trucks. Bulk quantities of hydrogen, carbon dioxide, helium, nitrous oxide, and various hydrocarbons (e.g., carbon monoxide) are delivered by transport of bulk liquid tanks or tank trailers which are transported to customer sites by rail and/or truck.

These transportable tanks may be ISO containers or trailer-mounted tanks. ISO tank containers are built based on ISO standards (International Organization for Standardization) and are designed to carry liquids in bulk, both hazardous and non-hazardous. These containers are made of stainless steel and are surrounded by various types of protective layers.

Gas Phase Tube Trailers

For gas phase products, gas supply options include tube trailers. Both single tube and multi-tube types can be used for transportation and onsite storage of gases such as helium and hydrogen, and sometimes other gases, such as nitrogen, oxygen and carbon dioxide. Tube trailers may be ISO tube trailers or trailer mounted high pressure storage cylinders.

Cylinders and Dewars

Liquid Phase Cylinders and Dewars

Liquid cylinders and Dewars are terms that are often used interchangeably, but the notable difference is that liquid cylinders are typically larger than Dewars and may be used for dispensing gas phase or liquid phase product. A Dewar is a storage vessel designed to deliver its contents in liquid form (i.e., into another container or immersion freezer). Transfer from a Dewar can be by simple pouring, or by use of a ladle or liquid withdrawal device.

Liquid cylinders are typically used until empty, and then exchanged for a full liquid cylinder. Dewars can be used and exchanged in the same way, or they can be refilled by a properly trained user with access to bulk supply or a liquid cylinder.

Gas Phase Cylinders

Cylinders are, of course, the gas supply options that represent the workhorses of the gas supply industry. Cylinders nearly always are intended to dispense gas phase product (either from gas phase contents or from the headspace above liquefied contents).

The typical gas cylinder is made from carbon steel. Some are made of stainless steel; some of aluminum. Cylinders used for corrosive gases are often passivated to reduce the reactivity of the inside walls of the cylinder.

Most cylinders are designed for high pressure use. Some cylinders, such as those used for propane and others used for acetylene, are low pressure cylinders. High pressure cylinders come in many sizes: a typical large cylinder is in the range of 9 – 10 inches in diameter and 50 – 55 inches tall. Small high pressure cylinders are in the range of 6 – 7 inches in diameter and 20 inches tall, sometimes smaller.

See also: Cylinder Diagrams

Portables and Lecture Bottles

Portable Cylinders

Portable cylinders, as the name implies, are small and lightweight. Low-pressure portable cylinders are most frequently used for calibration standards mixtures. The cylinder valving and associated hardware is designed for use with sampling devices, such as syringes and tedlar bags. Calibration standards are offered for EPA protocols, PEL monitors, air toxics monitoring, and other applications.

High-pressure portable cylinders are used for single component gases as well as mixtures. Portable cylinders are made from steel or aluminum, depending upon the pressure and contents. Importantly, not all portable cylinders are disposable, but some are. Please consult the package itself (or contact MATHESON) to determine the requirements for the package size and type in your possession.

MATHESON also offers a complete line of gas equipment, such as valves, flow rate regulators, and pressure regulators, designed for use with portable cylinders.

Lecture Bottles

Originally intended for use in education, lecture bottles, by design, are intended to be miniature versions of high pressure cylinders. Accordingly, many gases MATHESON offers are also offered in lecture bottles.

A complete line of lecture bottle regulators, including single and dual stage, and including brass and stainless steel, is also offered.

MATHESON is generally credited with the invention and development of the lecture bottle.