Gases for Metal Fabrication

Whatever gases and equipment you might need to support your welding and metal fabrication requirements, MATHESON locations offer answers and expertise.

Our representatives – in our stores and in the field – are trained AWS CWSRs (Certified Welding Sales Representatives). Many carry other AWS credentials. Expert training – and continuous training – puts us in a better position to offer expert support to all of our customers.

Rely on MATHESON for all of your gas needs. In fact, you can rely on MATHESON for everything welding.

Shielding Gas

Welders rely on shielding gases to ensure the integrity of their welds. Welders also rely on MATHESON – not just…

Fuel Gas

Fuel gases are a staple in every fabricator’s tool box – for brazing and soldering, as well as welding and…

Cutting Gas

Without regard for what you cut, where you cut, or how you cut, MATHESON is prepared to supply you with…

Welding and Cutting Automation

Automation in metal fabrication can improve worker satisfaction and safety while also improving productivity and cost per weld. In an…

Dust and Fume Removal

Your manufacturing processes may create welding smoke, fumes, grinding dust, etc. Your work or process may take place in poorly…

Vending Solutions

In large manufacturing sites as well as small-to-medium shops, the problem is the same: it’s easy to lose control over…

Laser Gases for Metal Fabrication

LaserPro™ gases and systems are designed to meet and exceed laser system manufacturer and user requirements including resonator gases, assist gases,…

Welding Expertise

Our Reps Can Lead You to the Right Products; Our SelectPRO Insight Program Can Help Improve Your Process. MATHESON inside and outside…

Welding Gas Purification

The WeldAssure Series of Nanochem® Purifiers helps to eliminate contamination, which is an unpredictable barrier to success in high technology welding. Shop WeldAssure…

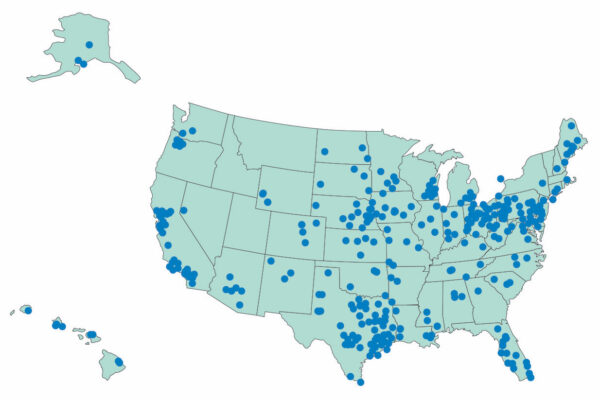

Welding Retail Locations

With over 160 Retail Locations across the country, MATHESON stands ready to meet all your welding needs: from gases and…