Batch Freezers at a Glance

Batch freezers are also known as Cabinet Freezers. There are no moving belts or tracks to transport product. Food product is loaded onto trays, slid into a rack, and the rack is pushed into the freezer. Rack and trays are then removed from cabinet after freezing is complete, and a new batch can be loaded.

Batch freezers can be single door or dual door; with double-batch models also available. The interior space behind each door is typically sized for standard 18 – 24 inch wide pan racks.

Versatile and low in cost – as well as fairly compact – batch freezers are a favorite of start up processors. They are also practical for use in new product development and for temporary installations.

Cryo Cool™ BF Cabinet Freezer

Maximum Output, Minimal Floor Space

The Cryo Cool BF Cabinet is a high-performance batch freezer designed for food processors faced with space limitations. This cabinet uses either liquid nitrogen or CO2 to help preserve flavor and minimize dehydration, making it an excellent choice for a wide range of applications, including prepared foods, meat, seafood, sushi, bakery products, and more.

Compliance with food safety standards is a top priority. The freezer’s stainless steel construction and dolly transfer system make cleanup and hygienic maintenance easy.

Utilizing MATHESON’s cryogenic cooling technology, the injection system adapts to changing heat load requirements, while fans circulate the cold vapor to optimize temperature control. Additionally, the user friendly controls make it a versatile and efficient solution for increasing productivity and product quality, all while minimizing capital investment and installation costs.

Maximum Output, Minimal Floor Space

MATHESON is uniquely qualified to support your business productivity and maximize your ROI. We are your one source for chilling and freezing equipment, gases, gas handling equipment, safety systems, installation, technical support, training, and maintenance. MATHESON’s team of food application specialists and engineers offers expertise in packaging, cooling, chilling, and freezing bakery goods, vegetables, fruits, all varieties of meat, ready meals, etc. — with Quality and Safety always the most important parts of the process.

View/Download Cryo Cool™ BF Cabinet brochure.

Standard Features

- Stainless steel construction

- Stainless steel wash-down fan motors

- Stainless steel fan blades

- Touchscreen controls

- Programmable recipes

Options

- Stainless rack and dolly

- Adjustable fan speed via variable frequency drives

- Push-through layout

- Dual-flow (fans on both sides)

- Exhaust blower

- Oxygen monitor

- Reversible layout

- Custom Sizes

Advantages

Better Product Quality

- Improved texture

- Better taste and appearance of the product

Flexibility

- Variable temperature

- Adjustable fan speed controls (optional)

- Conforms easily to any batch process

Excellent Yield and Efficiency

- Reduced dehydration

- Efficient cryogen consumption

Cost Effective

- Small space requirement

- Easy to operate, maintain and clean

- Low capital Investment

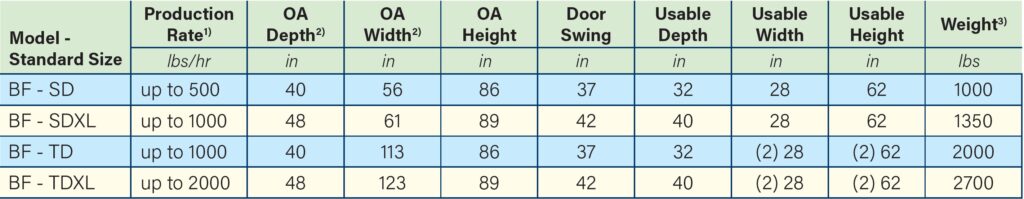

Standard Models (other sizes available)

1) Production rates are calculated for a typical case. For customer specific rates – contact sales support

2) Listed values are for standard layout. Push-through, dual-flow, and custom layouts will vary slightly.

3) Approxmiate values are listed. Weights may vary depending on layout option.

* LIN and LCO2 options available

** Standard voltages are 230/460V. Additional voltage 575V is available.