Automation in metal fabrication can improve worker satisfaction and safety while also improving productivity and cost per weld. In an industry with pressure on the availability of qualified workers, automation enables the human staff to upgrade to higher-value functions.

Automation Applications

On the metal fab shop floor, automation is well-suited to:

- cutting

- positioning

- welding

With many choices available, and many decisions to make, your MATHESON representative and automation specialist can offer valuable assistance to save you time and work with you while you navigate the options. Contact us.

Automation Choices

Numerous engineering choices put automation within reach for large and small operations.

Pre-engineered Cells use hard automation to “bake in” a full sequence of operations, and can be used for high value automation applications that will involve thousands, if not tens of thousands, of sequences from a single configuration. Pre-engineered Cells may or may not be integrated into other automation operations.

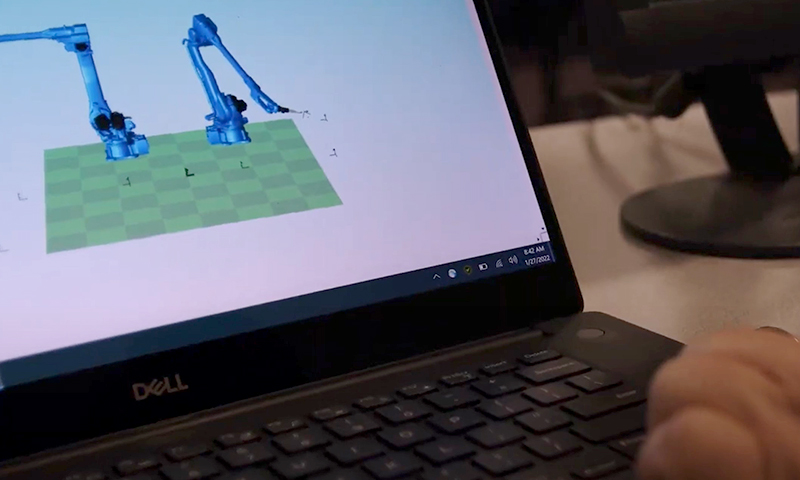

Fully Customizable Cells are typically intended for a single repeated operation (as opposed to a sequence of operations). Customizable Cells are designed to be “trained” easily by the end-user using a computer or tablet.

Collaborative Robot (Cobot) is a type of customizable cell that is small and transportable – designed to be moved around the shop and easily set up for a new operation without requiring much unproductive time spent in set up and shake-down.

Plasma Cutting is an ideal application for automation, since patterns and straight cuts can be repeated easily.

Other Applications for Automation

Systems for other types of automation – such as dust removal, fume extraction, and parts vending – are also offered by MATHESON. Read about them on this website, or contact your MATHESON rep or store location.