CHALLENGE:

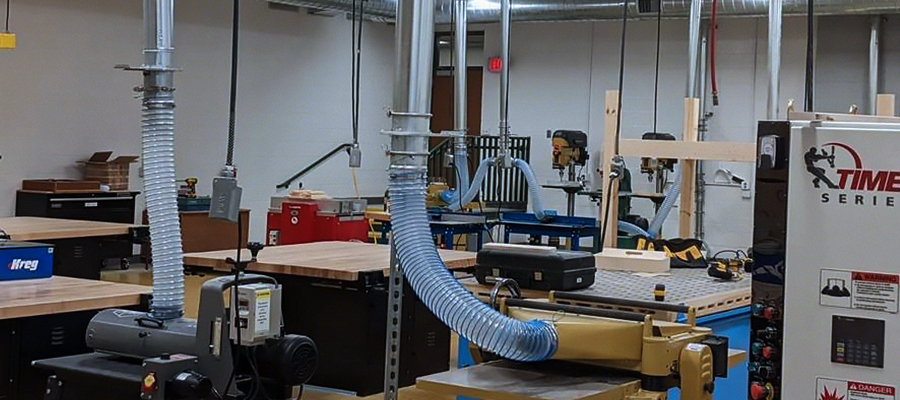

Wood dust is a simple and obvious indoor air quality problem with an easy remedy. Minimally, wood dust is an eye and respiratory irritant. In the worst case, indoors, under certain conditions, wood dust is an explosion and fire hazard. In every case, wood dust is a cleanup problem. Wood dust was a chronic problem in this eastern Nebraska High School. The variety of common wood shop tools – saws, planers, routers – spew dust daily. Students and instructors needed a solution that was both effective and compliant with various regulations and standards, such as those put forth by the NFPA (National Fire Protection Association).

SOLUTION:

The MATHESON Clean Air team worked with this school to provide a solution that would solve this wood dust problem. For dust removal efficacy, the wood working lab needed to be equipped with point-of-use dust collection as well as inlets for the collection of ambient air. Air and dust collected indoors would then be routed – at high velocity – through high capacity ductwork to a filtration and dust collection system module located outdoors. HEPA filters remove particles as small as 0.3 micron, and the air is returned to the workspace. Damper gates at the inlet and the outlet of the outdoor module serve to prevent reverse flow of air, particles, fumes, fire, and smoke as might be caused by a wood dust explosion or fire. The collector used in this application was equipped with an isolation device, deflagration device, explosion vent, detect and extinguish, and detect and abort system. The collector and the ductwork designed in this system was created to meet NFPA regulations for wood dust application.

SYSTEM BENEFITS:

- Filtration to particle size of 0.3 micron not only removes wood dust particles, but effectively cleans the air to a state that is “better than clean” (i.e., beyond simply the removal of the wood dust).

- Return of the cleaned air back into the workspace saves energy by reducing heat loss in winter and heat accretion in summer.

- Active dust removal reduces janitorial costs.

- Promotes compliance with NFPA 652, NFPA 654, NFPA 68 and NFPA 69 by removing wood dust and by isolating system elements to prevent reverse flow of smoke and fumes in the event of a deflagration.

- Filtration and residual dust collection components are located in the principal system component module outdoors for simplified system maintenance, cleaning, and dust cart-away.