Types of Tunnel Freezers

Flat Belt Tunnel Freezer

Tunnel freezers are easlily integrated into a production line or process. Capacity is determined by belt width, and freeze time is determined by the combination of belt speed and tunnel length.

Multi-Tier Flat Belt Tunnel Freezer

In this variation of a tunnel freezer, multiple belts are used. Typically, there will be three stacked belts (or in some models, five belts). At the end of the first belt, product is transferred to the second belt (which travels in the opposite direction); then to the third belt (traveling in the original direction); to the exit of the freezer.

The obvious advantages are more freeze time, less space, and a combination of the two.

Flighted Belt Tunnel Freezer

Ideal for IQF (individual quick freeze) of small food products, a flighted belt freezer uses three or more short belts that are inclined at an angle to induce product tumbling during the freezing process. The motion of the food products reduces the probablilty of the items freezing together, and enables IQF of items such as berries, diced meats, and vegetables.

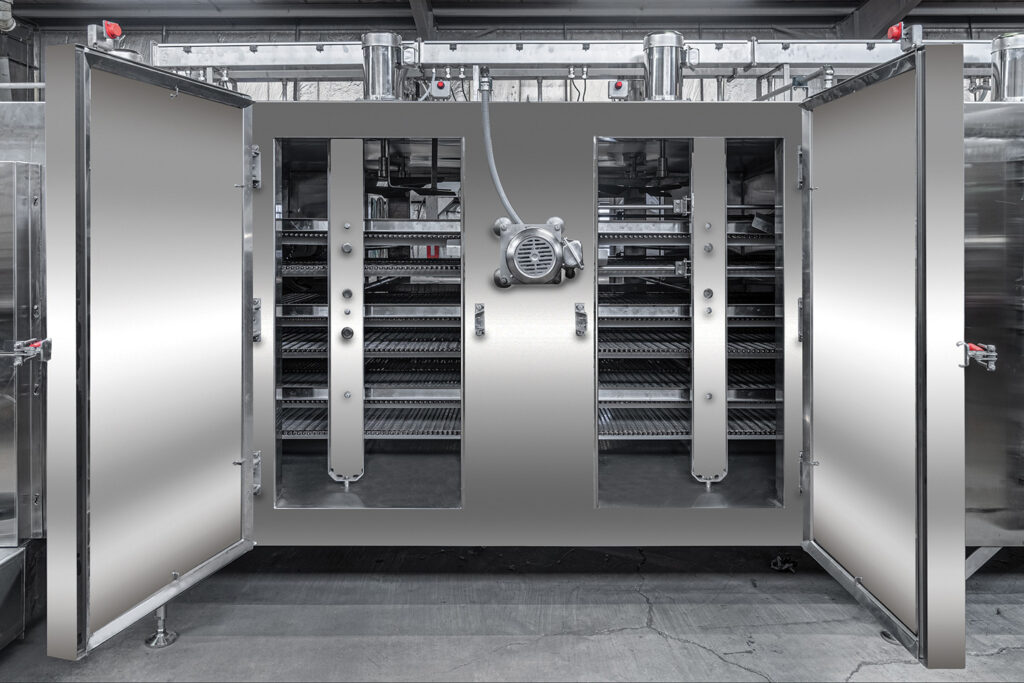

Cryo Cool™ 3XT Tunnel Freezer

The Cryo Cool 3XT Tunnel is perfect for the food processor with limited floor space. This multi-tiered tunnel maximizes in-line freezing capabilities and is designed to rapidly freeze your products with precision and efficiency. Utilizing three stacked conveyors, food cascades from tier to tier as it moves through the freezer. The combination of MATHESON’s cryogenic cooling technology, direct contact cryogen spray and balanced circulation ensures a uniform and consistent crust freeze.

Freezing Capacity Multiplied

MATHESON is uniquely qualified to support your business productivity and maximize your ROI. We are your one source for chilling and freezing equipment, gases, gas handling equipment, safety systems, installation, technical support, training, and maintenance.

MATHESON’s team of food application specialists and engineers offers expertise in packaging, cooling, chilling, and freezing bakery goods, vegetables, fruits, all varieties of meat, ready meals, etc. — with Quality and Safety always the most important parts of the process.

View/Download Cryo Cool™ 3XT Tunnel brochure.

Standard Features

- Stainless steel construction

- Adjustable legs for levelling

- Safety interlock system

- Nitrogen leak detection system

- Proportional control valve

- HMI touch screen

- Programmable recipes

- Full accessibility for easy cleaning

- Ethernet ready

- Modular construction for easy expansion

Options

- Belt tier transition dampers

- C.I.P. (clean-in-place) belt wash system

- Stainless steel exhaust blower

- Hydraulic top lifting, locker style door, or drop-down door for internal access

- Extended in-feed conveyor

- 5-pass models available

Advantages

Better Product Quality

- Improved texture

- Better taste and appearance of the product

Flexibility

- Variable temperature

- Variable speed controls for belts and circulation fans

Excellent Yield and Efficiency

- Reduced dehydration

- Efficient cryogen consumption

Cost Effective

- Small space requirement

- Easy to operate, maintain and clean

- Low capital Investment

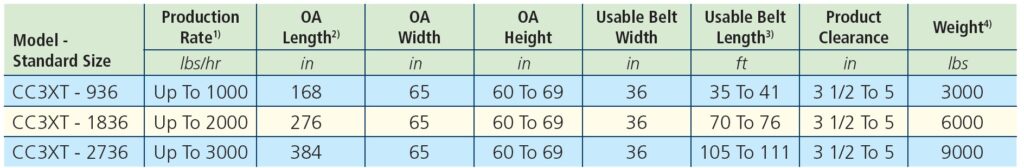

Standard Models (other sizes available)

1) Production rates are calculated for a typical case. For customer specific rates – contact sales support

2) Inlet and discharge extenstions may vary overall length

3) Approximate values are listed

4) Approximate values are listed. Weights may vary depending on belt option

* LIN and LCO2 options available

** Standard voltage is 480V. Additional voltages 230 & 575V are available